About

News and Events

Beamlines

- User Facilities

- Beamlines Directory

- BL08U1-A

- BL08U1-B

- BL09U

- BL13W1

- BL14W1

- BL14B1

- BL15U1

- BL16B1

- BL17U1

- BL01B1

- BL17B1

- BL18U1

- BL19U1

- BL19U2

Technology

- Accelerator Physics

- Accelerator Operations

- Radio Frequency

- Beam Instrumentation

- Control Systems

- Electronics & Detector

- Mechanical Engineering

- Vacuum

- Magnets

- Magnet Power Supplies

- Pulse Technique

- Cryogenics

- Front Ends

- Optics

User Information

Science and Publications

High Dislocation Density–induced Large Ductility in Deformed and Partitioned Steels

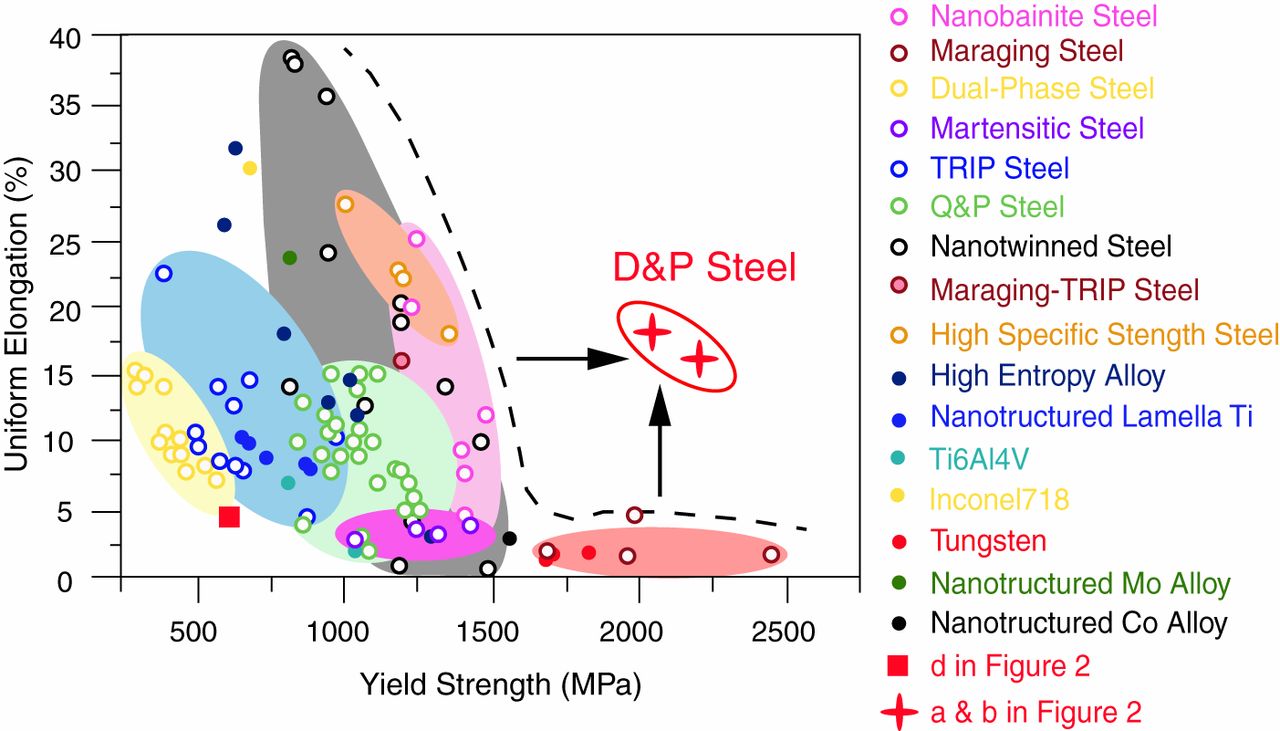

A wide variety of industrial applications require materials with high strength and ductility. Unfortunately, the strategies for increasing material strength, such as processing to create line defects (dislocations), tend to decrease ductility. We developed a strategy to circumvent this in inexpensive, medium Mn steel. Cold rolling followed by low-temperature tempering developed steel with metastable austenite grains embedded in a highly dislocated martensite matrix. This deformed and partitioned (D&P) process produced dislocation hardening, but retained high ductility both through the glide of intensive mobile dislocations and by allowing us to control martensitic transformation. The D&P strategy should apply to any other alloy with deformation-induced martensitic transformation and provides a pathway for development of high strength, high ductility materials. Synchrotron XRD experiments are conducted on the normal surface of the electro-polished sample in reflection mode at the BL14B1 beamline of the SSRF.

Tensile properties of our steel compared with those of other existing high strength metallic materials.

Links: DOI: 10.1126/science.aan0177

Copyright©2006.12 Shanghai Advanced Research Institute.

Copyright©2006.12 Shanghai Advanced Research Institute.