About

News and Events

Beamlines

- User Facilities

- Beamlines Directory

- BL08U1-A

- BL08U1-B

- BL09U

- BL13W1

- BL14W1

- BL14B1

- BL15U1

- BL16B1

- BL17U1

- BL01B1

- BL17B1

- BL18U1

- BL19U1

- BL19U2

Technology

- Accelerator Physics

- Accelerator Operations

- Radio Frequency

- Beam Instrumentation

- Control Systems

- Electronics & Detector

- Mechanical Engineering

- Vacuum

- Magnets

- Magnet Power Supplies

- Pulse Technique

- Cryogenics

- Front Ends

- Optics

User Information

Science and Publications

Optics

The Optics group supports technically construction of beamlines, on the optical metrology and fine mechanics test,

crystal fabrication, and engineering analysis etc. Main activities of the group are:

l optical metrology for the profile, slope error, roughness and radius of curve of mirrors or other optical

elements;

l check and inspection of movement precision of beamline components, such as monochromators,

mirror manipulators, etc.;

l engineering analysis of heat load, mechanical deformation and vibration by Finite Element

Analysis;

l crystal fabrication for hard x-ray monochromators, energy analyzers, scintillators, and so on;

l beamline survey and alignment.

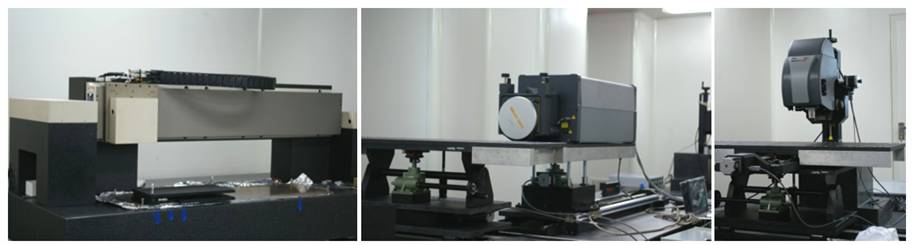

Optical Metrology

The main instruments include a long trace profiler LTP-1200, nanometer SSRF-NOM, ZYGO GPI XP/D

interferometer and ZygoNewView600S. Mirrors and bending system can be tested here.

|

|

LTP-1200 |

Zygo GPI XP/D |

Zygo Newview600s |

|

Accuracy |

0.83 mrad |

|

|

|

Resolution |

|

l/8,000 |

Vertical < 0.1 nm Lateral 0.36 to 5.18 µm |

|

RMS Repeatability |

0.1 mrad |

l/10,000(2s) |

< 0.01 nm |

|

Spatial resolution |

2 mm |

|

|

|

Maximum mirror slope |

1.8 mrad |

|

|

|

Maximum mirror length |

1.2 m |

152 mm |

|

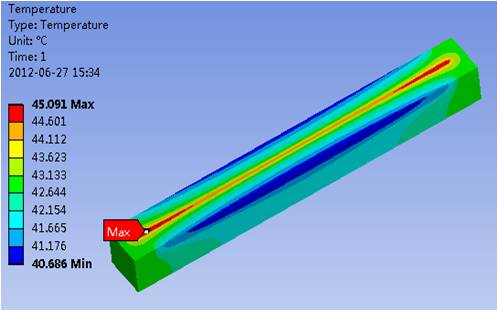

Engineering Analysis

Engineering analysis model is built based on the finite element method, and many kinds of analysis such as thermal,

structural and fluid analysis can be carried out to select better design schemes. Among them, thermal stress analysis

for high-heat-load components such as masks,filters and monochromators were indispensable because the

components in front ends will absorb much thermal power and the performance of optical elements in the beamline

was very sensitive to the deformation caused by heat load.

Temperature distributions of a collimator mirror

Crystal Fabrication

Crystal fabrication laboratory is used to manufacture different monochromators for beamlines. Its mission includes:

l Orient and measure the silicon single crystal.

l Process the silicon single crystal precisely.

l Develop and manufacture new crystal X-ray optics.

Orientation machine /Grinder machine/Thread cutting machine

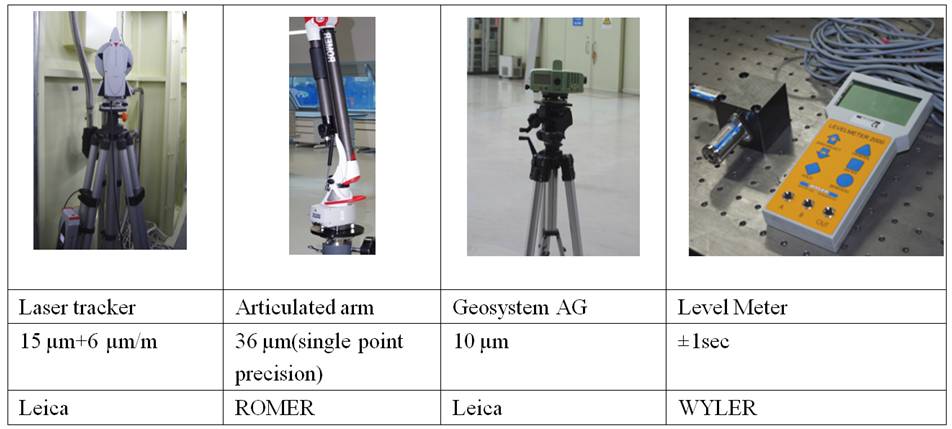

Beamline Survey and Alignment

The group is responsible for all aspects of front ends and beamline alignment, from initial installation to operation.

Some instruments were used in the survey and alignment processes, such as the laser tracker, articulated arm,

geosystem AG and level meter, etc., the main parameters of which are shown in the table.

The group is currently composed of 11 members.

|

Name |

|

|

Jie Wang |

wangjie@sinap.ac.cn |

|

Hongxin Luo |

luohongxin@sinap.ac.cn |

|

Yumei He |

heyumei@sinap.ac.cn |

|

Zhongmin Xu |

xuzhongmin@sinap.ac.cn |

|

Limin Jin |

|

|

Zhongliang Li |

lizhongliang@sinap.ac.cn |

|

Li Song |

songli@sinap.ac.cn |

|

Yifei Zhang |

zhangyifei@sinap.ac.cn |

|

Yichen Fan |

fanyichen@sinap.ac.cn |

|

Lian Xu |

xuelian@sinap.ac.cn |

|

Zengyan Zhang |

Copyright©2006.12 Shanghai Advanced Research Institute.

Copyright©2006.12 Shanghai Advanced Research Institute.