1.1 200-ton Large Volume press station 1 (LVP1)

The 200-ton large volume press station LVP1 contains a 200-ton DDIA large volume press (LPO 200-300/70, manufactured by Max Voggenreiter) and a multi-modes detector switching platform. The main ram of the 200-ton DDIA LVP has a max load of 200 ton with a full stroke of 70 mm. The DDIA module’s differential ram stroke is -1 mm to + 4 mm. Three different modes of compression are available for specific experimental purpose. The first is called cubic DIA compression with six first stage anvils. The edge sizes of the anvils are either 3 or 6 mm. The second mode is cubic 6-6 compression with first stage anvils of 27 mm edge. In these two modes, both isotropic and anisotropic compression experiments can be carried out. The third mode is the conventional 6-8 compression with first stage anvils of 27 mm edge and second stage anvils of 14 mm edge. Normally up to 10 GPa pressure can be generated by this 200-ton LVP. Higher pressures up to 20 GPa can be achieved by employing sintered diamond as the second stage anvils using 6-8 cell assembly.

A heating system is installed in the 200-ton multianvil, equipped with a 3 kW AC power and five alternative outputs: 5V/600A, 7.5V/400A, 10V/300A, 15V/200A, and 40V/75A. The sample temperature is expected to up to 2000 K, depending on the heater materials.

Energy dispersive X ray diffraction (ED-XRD) as well as high energy imaging are available in LVP1 for sample characterization under high pressure and high temperature condition. For EDXRD, a Mirion (Canberra) high-purity germanium (HP-Ge) solid-state detector is installed on the detector switching platform. In situ sample/cell’s images are monitored by an Optique Peter X-ray microscope. High energy imaging can also be taken by the same X-ay microscope if necessary. These characterization techniques are switchable according to demand. In this hutch, the “gauge volume/length” are usually ~ 1 to 2 mm determined by the geometry of the collimator system and incident beam size. 2θ diffraction angle of ~ 6° and incident beam size of 100 μm are typically used.

Fig.2. View of the LVP1 experimental hutch

1.2 2000-ton Large Volume press station 2 (LVP2)

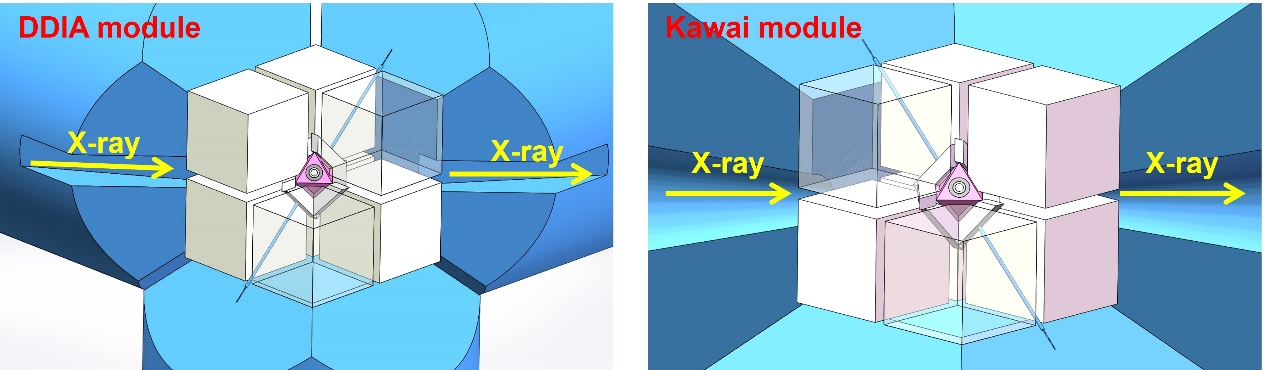

The LVP2 experimental hutch is located in the external building of BL12SW. A 2000-ton multi-anvil apparatus (LPO 2000-710/80, manufactured by Max Voggenreiter) is installed with dual modules of DDIA and Kawai. The max load of the main ram is 2000 ton with a full stroke of 80 mm. The DDIA module’s differential ram stroke is -10 mm to +10 mm. The displacements of two vertical differential and four equatorial anvils are measured individually by stroke gauges. The DDIA and Kawai modules are interchangeable automatically driven by a bus carrier. The upper blocks of both modules can be lifted by a hydraulic lifting unit. The sample with lower block is moved further to the ending load position of the rail for recovery.

For the Kawai module, a typical 6-8 cell assembly with 1 inch second stage anvils is used for high pressure experiment. Two types of first stage anvils of DDIA module are available for users. One is the tungsten carbide anvils of 27 mm edge size designed for 6-6 cell assemble as well as 6-8 assemble with which isotropic compressional and deformation experiments can also be carried out. The other type is the conventional 49 mm first stage steel anvils designed for 6-8 assembly with 1 inch second stage anvils. With carefully design, sample pressure can be achieved up to 35 GPa.

In situ high temperature condition is also available in 2000-ton LVP. Its heating system has a 6 kW AC power and five alternative outputs: 8 V/750 A, 15 V/400 A, 20 V/300 A, 30 V/200 A, and 50 V/120 A. The highest sample temperature is expected to up to 2100 K, depending on the heater materials.

EDXRD as well as high energy imaging are also available in LVP2, and the setup are similar to that of LVP1. In addition, angle dispersive X-ray diffraction (AD-XRD) experiments can also be carried out with a Rayonix SX165 CCD detector (pixel array 2048 × 2048, pixel size 80 μm, 16-bit image), if sintered diamond second stage anvils are used. A portable 17-inch iRay Mercu 1717V (pixel array 3072 × 3072, pixel size 139 μm, 16-bit image) image plate is also available.

Fig.3. View of the LVP2 experimental hutch

Fig.4. Schematic illustration of 6-8 cell assembly

1.3 Engineering materials station 1 (ENG1)

The engineering materials station 1 (ENG1) is located in the main building right next to the LVP1 station. This station is designed especially for experiments on mm-cm-scale samples and small in-situ devices. The station is equipped with a high precision nine-axis sample stage for diffraction and imaging, which consists mainly of a 5-axis bottom stage and a removable air-bearing rotation stage (4-axis). The bottom sample stage has a vertical adjustment axis (Z1), a 360° rotation angle (Phi), and two tilt axes (X-tilt and Y-tilt) and a long translation axis (X). The air-bearing stage contains a vertical adjustment axis (Z2), two position adjustment axes (X2, Y2), and a continuous gas-driven rotation axis. The maximum rotation speed of the air bearing stage is 200 rpm, which is suitable for rapid CT experiments. The maximum load capacity of the bottom sample stage is 200 kg, and the maximum load capacity of the air-bearing high-speed stage is 50 kg at its static state.

A detector switching platform is installed next to the sample stage for detector supporting. The platform consists 5 modules. Each module has independent driven mechanisms allowing detectors moving along the beam direction in a long range of 2 m and switching between different detectors referring to different experimental methods. A Pilatus3 X CdTe 2M detector and a multi-module imaging system are currently equipped in ENG1 to carry out high energy XRD, PDF, as well as 2D imaging and CT. The imaging system consists of two fixed-magnification modules and one zoom module. The magnifications are 2X, 7.X, and 0.28-1.8X, respectively. The best resolution of imaging system achieved is ~2 µm with the PCO edge 5.5 CMOS (6.5 µm per pixel). Moreover, a high-speed camera FASTCAM Mini UX100 is also available for high-speed imaging. Spare detector modules are reserved for potential experimental methods upgradation. Especially the one at the end of the hutch can be used for large-angle diffraction and phase-contrast imaging.

Fig.5. View of the ENG1 experimental hutch.

1.4 Engineering materials station 2 (ENG2)

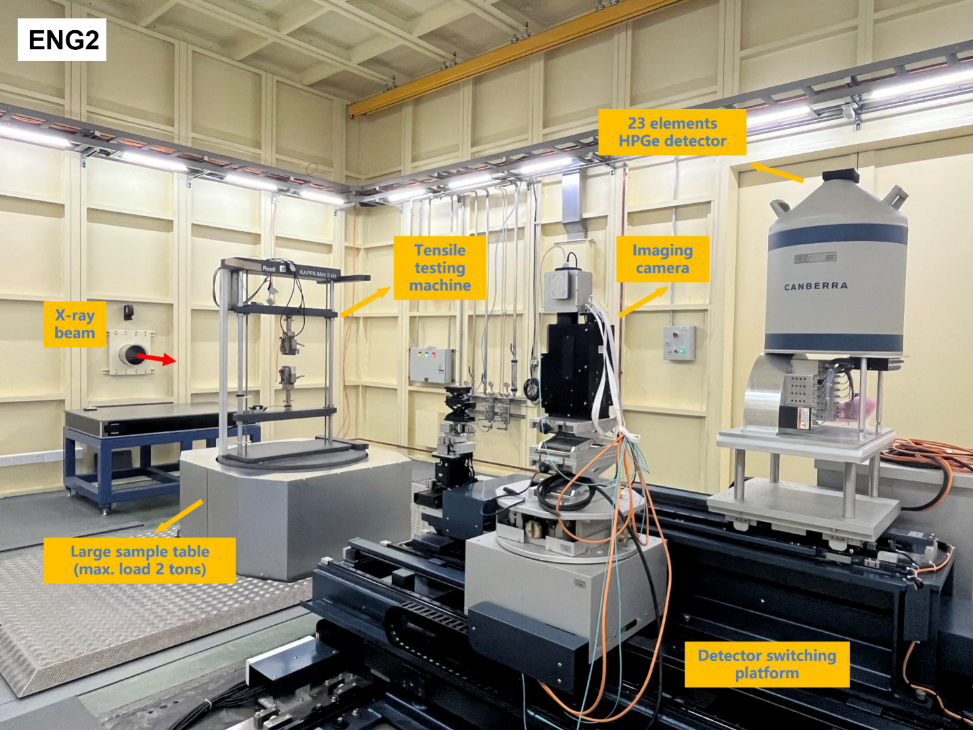

The engineering materials station 2 (ENG2) is located at the end of the beamline, which is specially designed for experiments on oversize samples (up to 2 tons in weight) and in-situ equipment. The size of this hutch is 11 m × 7 m × 5 m and with a 3-ton electronical crane, making it convenient entry and exit of large equipment. A specially designed sample stage is installed 3m under the ground. The maximum load bearing capacity of this stage is 2 tons, and its top surface is almost flush with the ground at the lowest position leaving enough space for industrial large samples and in-situ equipment in real-service environments. More importantly, this stage also has a 5 axes high precision adjusting mechanism. Especially, the vertical Z axis allows the stage move up to 1 m, making this stage extremely in situ experiments friendly with the help of high energy characterization techniques.

ENG2 also has a similar detector switching platform as ENG1. It has 4 modules for detectors supporting. The function of this platform is the same as that in ENG1. But it must be pointed out that a 23-elements HP-Ge detector is equipped in this hutch, which is used for energy-dispersive diffraction. A complex two slits collimation system is also added to the detector to increase the resolution of the system. Therefore, the 23-element HP-Ge detector can be used to detect the internal stress distribution and strain tensor of materials. In addition, a large field of view imaging system with a 100 mm FOV is also planned to be installed in this hutch for upgradation.

Fig.6. View of the ENG2 experimental hutch

附件下载: